At ELKA, we continuously prioritize responsibility in the development and manufacturing of functional, high-quality workwear. It is particularly important for ELKA to ensure that our products remain in use for as long as possible, and we strive to achieve this in several ways.

We collaborate with customers and end-users to create functional clothing, ensuring a high demand for the products we develop. During the product development phase, we prioritize selecting high-quality raw materials to provide the best possible foundation for a long product lifespan.

We also incorporate elements into the design that allow the product to serve multiple purposes. This means that we emphasize designing our products, for example, with zip-in/zip-out functionality or detachable sleeves to easily adapt to different needs in changing weather conditions.

Concerning aesthetic design, we draw inspiration from Nordic minimalism and deliberately avoid incorporating period-typical elements that could shorten the product’s lifespan due to changing fashion trends.

All of these efforts contribute to extending the lifespan of our products, making them as durable as possible.

WE KEEP A CLOSE EYE ON THE CHEMICALS

ELKA’s production of workwear is based on a chemical strategy. This strategy has been developed in close collaboration with Bureau Veritas in Denmark, a leading company in terms of quality, environment, work environment, safety and social responsibility. As part of this collaboration, a testing program is included, where we regularly test the content of chemicals in selected products. For testing, ELKA always use a third-party laboratory, and often, the tests will be carried out by a Bureau Veritas laboratory.

BSCI OR SEDEX CERTIFIED PARTNERS

We focus on ensuring responsibility, also in our supply chain. Therefore, all our suppliers from the East are either BSCI (The Business Social Compliance Initiative) or Sedex (Supplier Ethical Data Exchange) certified. Both are global organizations that focus on helping companies be ethically and socially responsible.

WE COMPLY WITH REACH

All ELKA’s products are produced in accordance with REACH. REACH is the EU’s basic chemical legislation, and the term stands for “Registration, Evaluation, Authorization and Restriction of Chemicals”. The REACH regulation is, among other things, adopted to improve the protection of human health and the environment against the risks chemicals may cause.

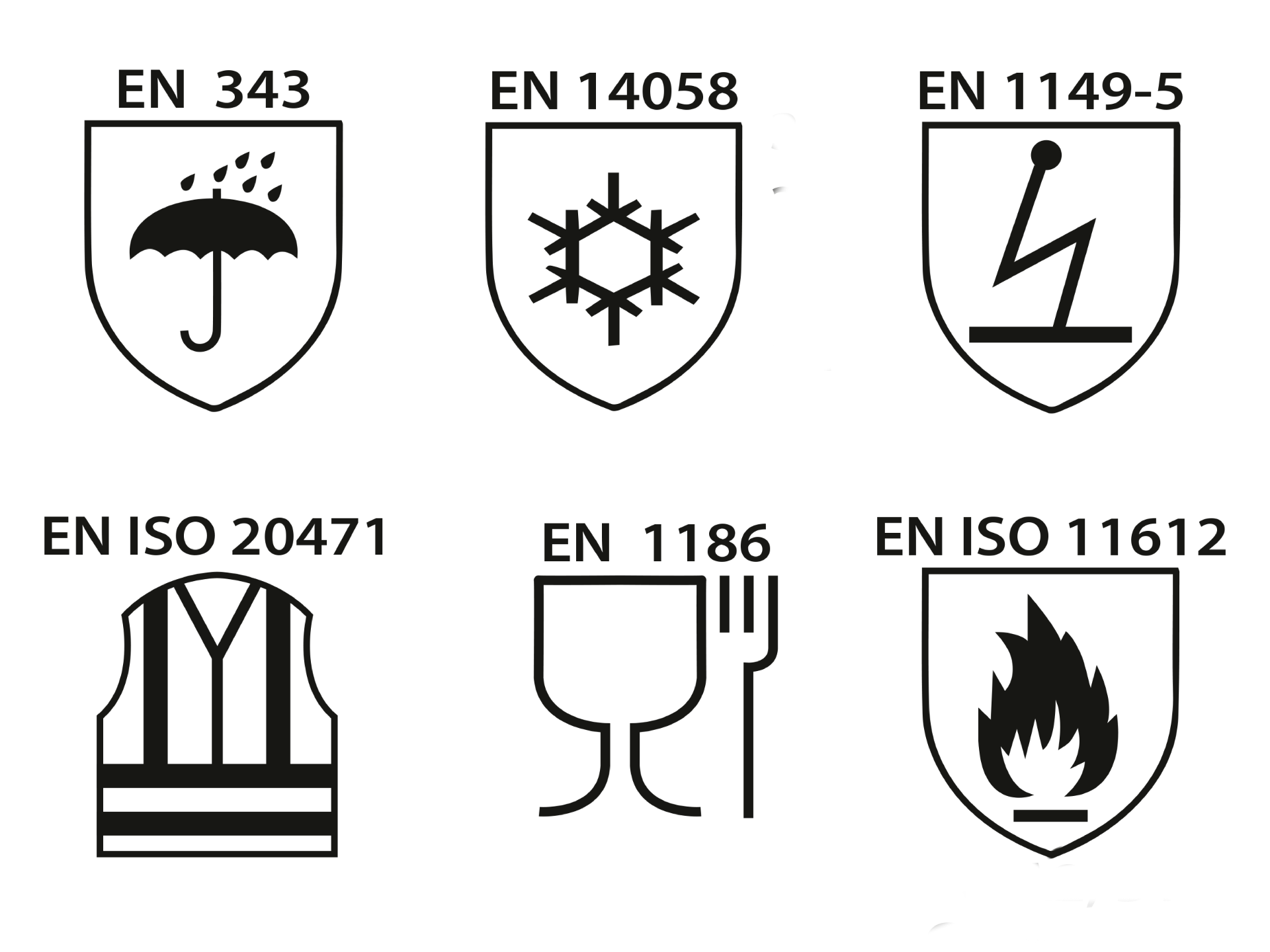

EUROPEAN CERTIFICATIONS

The majority of the ELKA range meets the requirement for PPE personal protective equipment, approved by accredited test institutes. The norms for each standard are tested on the product, to pass the EU-set standards for safety and performance.

OEKO-TEX® STANDARD 100

Selected products in the ELKA range are certified according to OEKO-TEX® STANDARD 100. This standard is one of the world’s best-known labels for textiles tested for harmful substances.

EUROPEAN PRODUCTION

We are pleased to offer production at our own factory in Europe, geographically close to our head office in Denmark. In total, approx. 50% of our garments are made in Europe, with fabrics and trim of European origin.

RECYCLED BY ELKA

We have initiated a process where we incorporate the use of recycled materials in the manufacturing of our workwear.

![]()

WE TRY TO REDUCE WASTE

We are focused on minimizing waste, both in our products and at ELKA as a workplace. In our products, for example, we have changed the practice regarding extra accessories. We no longer include extra buttons with our products, and we no longer provide glue for repairs in our waders products – because we want save the environment for a lot of waste. If our customers require these items in specific cases, we are happy to assist.

Similarly, we have changed the way we package our braces for overalls. Previously, they were in a separate plastic bag, now they are folded inside the product as we aim to reduce the use of plastic bags.

At ELKA as a workplace, we have also implemented new initiatives and changed routines. Heat pumps have replaced oil furnace, lighting has been switched to LED, cardboard and plastic are sent for recycling, and we minimize paper and printing by using multiple screens. Additionally, we have installed solar panels at our factory in Lithuania.

PFAS-FREE PRODUCTION

At ELKA, we use a PFAS-free surface treatment on our waterproof workwear and rainwear. This advanced technology ensures effective water repellency, protecting the fabric from rain and dirt while keeping you dry and comfortable.

With increasing attention on the impact of traditional water-repellent treatments - often containing fluorine-based chemicals such as PFAS - we made an important decision in early 2023. We transitioned our production to exclusively PFAS-free treatments across all our products.

This transition ensures that all products manufactured after this change meet the highest standards. At the same time, we continue to deliver workwear with the durability and functionality that professionals rely on in their daily work, focusing on creating thoughtful and innovative solutions for the future.